Controlling Condensation with Aerolon

Problem

Condensation occurs when there is enough humidity in the atmosphere and a cold enough temperature that allows the humidity in gaseous form to revert back to liquid form. The two driving parameters of whether this happens or not (on a surface), is the temperature of the substrate relative to the atmospheric temperature and the amount of humidity in the atmosphere. This process is best understood by observing water (from atmospheric humidity) condensing on a cold can of soda in the summertime.

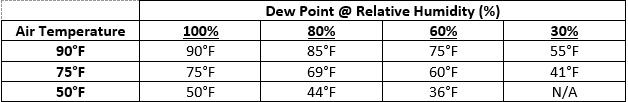

At any given air temperature and relative humidity there is a corresponding dew point. The dew point can vary from morning to evening, and from season to season, depending on humidity (often lower in the colder months). The chart below shows the different dew points given a certain air temperature and relative humidity:

One can see that the dew point rises with increasing humidity; and also rises with increasing temperature.

When a substrate is colder than the dew point - condensation forms. Process vessels, piping, gas lines, north facing tank or building sides, etc. can all be (at times) below the dew point. It is not uncommon to see the north sides of storage tanks or the bottom half of railcars “sweating” in the morning; because the sun has not yet warmed them. Shaded areas also have lower temperatures and dew points, where condensation can be present given equal humidity in the air. The infrequent (or constant) presence of water on steel substrates can lead to corrosion, unless properly protected. Wet pipes or vessels dripping on the floor can present worker safety issues, particularly if microorganisms begin to thrive, making floors extremely slippery.

Solution

Not all “sweating” surfaces pose a problem; but when safety is compromised or severe corrosion is taking place, prevention or remediation is required. Aerolon is a thin-film, spray-applied insulation coating that uses the world’s best insulating material – aerogel. Aerolon incorporates aerogel in an acrylic binder matrix, effectively trapping air within its layer. While Aerolon is quite effective at insulating hot substrates, it is equally effective at insulating cold surfaces. Providing an insulating layer over a cold surface can raise the outside surface temperature of the structure to approach the ambient temperature. In essence, it can also raise the effective dew point of the structure to prevent condensation.

As pointed out in the discussion above, the actual dew point varies from moment to moment (time of day) and is dependent on the relative humidity and ambient air temperature. By applying a sufficient thickness of Aerolon over a cold surface, we can insulate the surface and effectively raise the surface temperature above the dew point. This thickness will vary depending on whether your pipe or vessel is in Houston, TX or in Phoenix, AZ where the relative humidity can be vastly different.

In order to calculate the correct thickness needed, one needs to know the average or determined surface temperature, the relative humidity, and the ambient air temperature. One might take the worst-case scenario (high humidity and high temperature) to calculate a thickness where condensation never occurs; or find a compromise thickness where only minor condensation occurs but evaporates before safety becomes an issue. Tnemec, a supplier of the Aerolon product, and Coblaco, industrial coating specialists, have partnered to assist customers in making this evaluation.

Engineered Approach

In order to enjoy all the benefits of Aerolon, it must be engineered (designed and applied to product specifications) for your particular project. Coblaco understands that the right surface preparation and application of Aerolon is critical to its performance and has partnered with Tnemec to make sure that Aerolon delivers for your specific needs.

Coblaco Services Inc. has been in business since 1978. We are an industrial services contractor providing solutions for challenging projects. We are best known for:

· Project Management - We manage our projects so our customers do not have to.

· Industry Knowledge - Our industry knowledge and certifications lead us to being solutions driven.

· Responsive - Our ability quickly respond is the result of our ability to scale.

For more information, click on link below for article by John H. Strine and Andy Hoffman, “Coatings Help Control Condensation,” OpFlow Magazine, Feb. 2019.